Antioxidant products can prevent polymers from undergoing chemical reactions or degradation during processing due to heat, shear stress, or exposure to other harsh processing environments. These reactions or degradation can lead to changes in the chemical composition or molecular weight of the product. Additionally, it can result in the deterioration of mechanical properties and affect the appearance, causing changes in the color of the polymer or a reduction in glossiness.

Antioxidants are products added to polymers during processing to protect the polymer's structure and prevent discoloration.

Phenolic Antioxidants

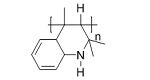

| Phenolic Antioxidants | Chemical structure | Type | Molecular Weight | Melting point ℃ | TGA (°C, % weight loss) |

Applications |

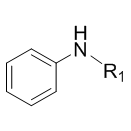

| Naugard® 445 |

|

Powder/ |

406 |

98-100 |

305 10% 346 50% |

Used as heat stabilizers in various applications including polyolefins, styrenics, hot melt adhesives, and polyamides. |

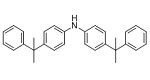

| Octamine® |

|

粉狀/ |

393 |

90-97 |

– |

Solid amine antioxidants that minimize discoloration effects while providing maximum protection. |

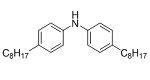

| Naugard® Q |

|

Granule |

874 |

120-125 |

297 10% 465 50% |

Effective processing and long-term heat stabilizers, particularly effective in carbon black-filled polymer systems. |

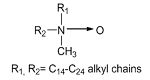

| Genox® EP |

|

Powder |

613 |

85-105 |

– |

High-performance melt processing stabilizers with excellent resistance to gas fading. |